Upgrade or Replace: A Cost Comparison of Australian Warship Service Lives

28 Apr 2017

By Alastair Cooper and James Mugg for Australian Strategic Policy Institute (ASPI)

This article was external pageoriginally publishedcall_made by the external pageAustralian Strategic Policy Institute (ASPI)call_made on 13 April 2017.

This analysis of warship service life options comes at a time when Australia is planning to embark upon a substantial naval shipbuilding venture. The Australian Government is first and foremost seeking a domestic build for the next generation of warships, but more broadly intends to stand up an indefinitely sustainable domestic shipbuilding industry.

Australia has for several decades pursued a stop–start warship acquisition process, in which most vessels serve for about 30 years, generally including a major mid-life upgrade. The decision to pursue a continuous shipbuilding program now provides a chance to consider alternative models for the provision of warfighting capability. This Strategic Insights looks at the implications of warship service life for the overall cost-of-ownership and the operation of the RAN as an enterprise, and proposes options for consideration in the development of the future submarine and frigate programs.

The publicly available costings suggest that there’s little difference in the annual cost of ownership between a 30-year-plus-upgrade service life and a 20-year-without-upgrade service life. That creates the possibility that the future frigate and submarine programs can consider service life options that enable other parts of the Navy to be optimised.

Because ships are the lynchpins for the sophisticated networks making up the enterprise, decisions affecting ship service life have direct implications for the naval enterprise and reverberate through the rest of Defence. To simplify the analysis, this paper compares a nominal 20-year service life with no major mid-life upgrade to a nominal 30-year service life that includes a major mid-life upgrade.

Whole-of-life costs

Acquisition and maintenance costs are significant factors to consider in assessing the relative merits of different service life options. Because the acquisition cost is amortised over the vessel’s lifetime, it’s plausible that a shorter service life makes a warship more expensive in the whole-of-life sense. If that were the case, a 30-year service life would be better than a 20-year service life because of the longer amortisation period. But the initial purchase cost is only one part of the cost of a warship; crew costs, maintenance, refits and upgrades must also be included to understand the total cost of ownership over a ship’s lifetime.

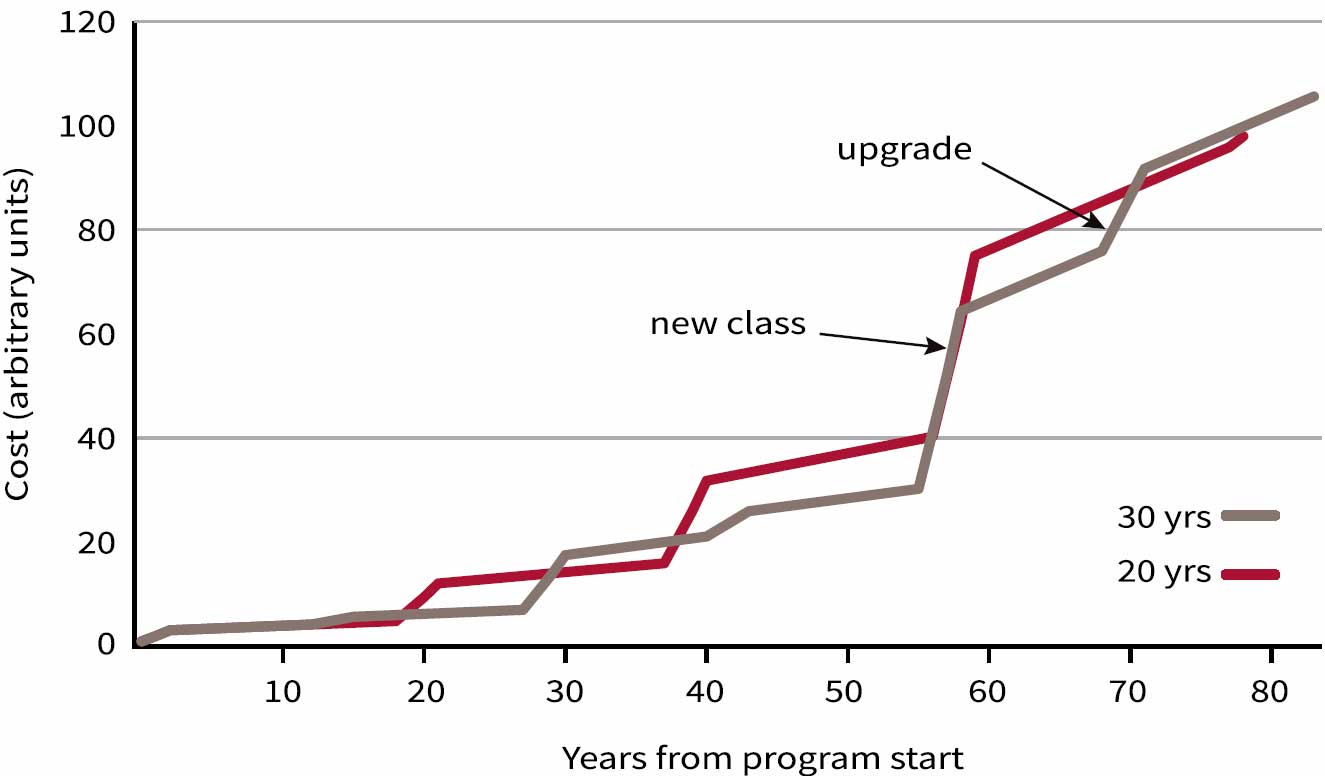

Figure 1 shows an indicative comparison of two hypothetical shipbuilding plans. The first is the model employed by Australia and many other modern navies, in which a vessel receives a significant upgrade roughly halfway through its 30-year service life. The second model shows an alternative shipbuilding program in which a vessel is retained for only 20 years before being replaced. In both models, each vessel iteration is more expensive than the last (the cost growth is matched to historical data). The model assumes that the operating costs increase in proportion to the acquisition cost, since the vessel’s complexity drives both. This chart shows the cumulative cost over time for the two approaches.

At various times in the 80-year period shown, neither strategy is cumulatively more expensive, but the curves tend to ‘leapfrog’ when each successive class is built. The conclusion is that the biggest driver of the cost of maintaining a frontline navy is the steep increase in the cost of follow-on classes due to real cost increases for capability. Any savings that might accrue in the 30-year strategy from amortising the build cost over an additional 10 years is offset by the greater cost of the follow-on class. This is a simple model, and real life data will be less regular, but the broad conclusion that replacement costs dominate the long-term cost of naval capability is entirely consistent with observed trends in naval force structure around the world.

Figure 1: Cumulative costs of the two strategies

Using the cost information in Department of Defence annual reports, it’s possible to (roughly) assess the total cost of ownership for current Australian ship classes. Table 1 sets out the published build, upgrade and sustainment costs for the Adelaide-class guided missile frigates, Collins-class submarines and Anzac-class frigates, and calculates the cost per vessel per year. The costs have been adjusted for inflation to use Australian dollars in 2016 as the base. The calculation also assumes that after 20 years of service life a vessel’s operational value is effectively zero, and so it must either be replaced or refurbished and upgraded. The sustainment costs for all three classes are available as a consistent series only since the 2007–08 financial year, so there’s insufficient coverage of the existing classes’ service lives to clearly demonstrate any long-term trends (such as the bathtub curve that was anticipated by the 2011 Rizzo Report).1 For the purposes of this analysis, consistent with the available data, we use a constant sustainment cost in the initial analysis and discuss the implications of cost increases later.

Table 1: Amortised annual cost per vessel in service (A$ millions 2016)

Note: A full detailed table is in the Appendix.

Within the uncertainties of the available data, there’s no clear difference in support costs between the 20-year and 30-year approaches. The published data suggests that the per-year, amortised cost of ownership for each of the Australian Navy’s three major combatant classes varies by less than 10% between the 20-year and 30-year service life options. The Adelaide case indicates a 20-year service life as the least cost option, and the Collins and Anzac cases indicate a 30-year service life as the least cost option.

While there’s no basis in the Australian data for a bathtub effect, it makes little difference in practice. If we assume that there’s a 10% premium for sustaining an ageing platform (service life 21–30 years), then the Collins model indicates that the 20- and 30‑year options would be effectively equal cost, while the Anzac 30-year option remains the least cost. If there’s no such premium on sustaining an ageing platform, it may in some cases be worth the additional 10% of expense for a new, distinct platform. And it may avoid some of the complications that come with adding new capabilities to older platforms—commonality is an often-undervalued efficiency.

The crew costs over a class’s life must also be considered when assessing the overall cost of ownership. For example, the addition of new systems to an existing platform, whether part of a mid-life upgrade or not, will tend to increase the crew numbers simply because the new systems need operators and maintainers. Using the Adelaide-class FFGs (183 crew on commissioning, 199 in 2017) or Anzac FFHs (163 on commissioning, 177 in 2017) as examples, a ship in the last decade of its life could have a crewing requirement around 5–10% greater than in its first decade, equating to 10–15 additional crew. If each crew member costs an average of $200,000/year, the extra crew cost for an ageing platform could be $2–3 million/year for a surface vessel—just a few percent of the overall sustainment cost in any case. The space and weight constraints of submarines might preclude such significant crew increases, but the boats could still be subject to calls for lesser additions. While a new design may or may not have a smaller crew, it’s likely to be able to utilise the crew more efficiently.

The above data uses current classes as a template, which might not necessarily translate directly to Australia’s future frigate and submarine programs. The current major combatants were acquired using a start–stop approach, each with a different design heritage and team that may not have been easily available to plan upgrades. So the design, planning and execution of mid-life upgrades were almost certainly more unpredictable, difficult and expensive than they would have been as part of a continuous design and construction program.

By way of comparison, the US Navy’s Arleigh Burke-class program gives an indication of what’s possible. The first Arleigh Burke cost US$1.1 billion to build (US$2 billion in 2015 dollars, adjusted for inflation2), while in 2015 the build cost of the most recent (and therefore most capable) Flight III Arleigh Burke has been estimated to be about US$1.7 billion.3 The Flight III was conceptualised in response to the truncation of the expensive Zumwalt class and demonstrates how an entirely new baseline design may not be the only way to increased capability. By modifying an in-service design, the US Navy can reduce the technical risk of the program.

At the same time, several of the older Arleigh Burke-class ships are being upgraded and having their hulls revitalised, which will extend the service lives of some of the earliest vessels in the class to about 40 years. This approach allows the US Navy to keep a greater number of large combatants in service as the old Ticonderoga cruisers retire, while introducing new capabilities through both old and new-build vessels. If the Flight III ships are all built, the Arleigh Burke class could have a heritage of more than 60 years.

The conclusion that can be drawn is that a continuous design and construction approach enables flexible replacement and upgrade options that might otherwise be unavailable. Either an upgrade or a replacement approach—or both—can be chosen, depending on the considerations of the day, whether they be strategic, fiscal or otherwise.

Organisational impact

The ability to conduct a mid-life upgrade must also be considered as part of the comparison between the 20-year and 30-year-plus-upgrade options. Although warships are almost continuously upgraded in different ways, by about the 20-year mark a major midlife upgrade is required for two distinct but equally important reasons: first, to ensure that the structure and platform systems remain capable for combat conditions (not just for routine service) and are upgraded when necessary or desirable; second, to allow for the fitting of new weapon, combat and communication systems and their integration with legacy systems and the platform itself.

Just to carry out such an upgrade is a significant undertaking, often similar in complexity and scale to designing and building a new vessel. Both a new build and an upgrade have a big impact on the Navy enterprise; the provision of trained crews and logistic support arrangements are two major examples. New systems require personnel with new skills to operate and maintain them, so the Navy training pipeline must evolve to have a continuous supply ready for when the ship completes its upgrade. Similarly, the supply system must have appropriate parts and consumables for the new systems. Equivalent adjustment also occurs in the industry parts of the Navy enterprise, the importance of which shouldn’t be underestimated: the ability for the Navy to be a reliable contracting partner has an impact on the overall value-for-money outcome.

If the delivery of any one element is delayed—the completion of the ship upgrade or build itself is the most obvious—then the cost to the Navy of the overall process increases. While the cost might not be seen in the project itself, the overall Navy enterprise will be forced to adapt to the delay, and the costs will accrue in disparate parts. The programs for other ships will need to be adjusted in large and small ways: dockings will need to be rescheduled and training and operational commitments deferred or met with different platforms.

In some cases, there will be alternatives or contingency in the system; in some cases, there won’t. The delays in the completion of the Hobart-class DDGs give an indication of the impact. In that case, not only did the Navy enterprise need to continue to maintain and operate old vessels (the Adelaide-class FFGs) for longer than originally planned, but the number of rescheduling processes for the completion meant that the provision of a trained crew and supply arrangements had to be adjusted the same number of times. (Given the fraught nature of warship building in Australia over the past decades, it wouldn’t have been acceptable for there to be any suggestion that a ship’s entry into service was delayed due to a lack of crew.) An important conclusion from this analysis is that schedule performance—predictability—has a broad impact on the whole Navy enterprise (not just the upgrade or build project) and should be valued accordingly.

Technological development and lead times

While predictability is highly desirable for both new builds and mid-life upgrades, it’s easier to plan to achieve it at the new-build stage. In a new build, the technology to be incorporated can be accounted for in the design process. For a mid-life upgrade 15 or 20 years hence, while the general outlines of technological developments can be described, much of the detail needed to plan an upgrade is simply unknown and hence unpredictable. Moreover, depending on the size of the development, there might be a lead time of 5–10 years to plan and implement it, particularly if it’s part of a package of work in a mid-life upgrade. This brings cost and engineering problems that can’t necessarily be accounted for in the design process, even when the vessel is given significant margins for space and weight growth. Nonetheless, growth margins at design are still important, as technological refreshes and the fielding of new systems throughout the vessels lifetime are important to ensure combat capability is retained throughout service life.

Some technological upgrades can be incorporated within existing physical structures: Standard/Tartar missiles were fired from Mk13 launchers designed to fit in the same space as a Mk54 5-inch gun mounting, and software upgrades or upgraded computer processors don’t necessarily need significant physical changes. But some technological upgrades might require major changes to or even the replacement of the existing physical structure: the incorporation of new materials for aircraft is one example, but new uses of existing ones could lead to the same result. For example, new technologies for signature minimisation and the ability to withstand combat damage are usually most efficiently incorporated at the design stage. The attempts to retrofit radar-absorbent material to the Adelaide-class frigates didn’t achieve the same level of signature reduction as might have been possible if it had been fitted as part of the design and construction; nor would it have resulted in the same cost to maintain the underlying vessel structure against corrosion. In some cases, new weapons systems require much greater outputs from platform systems; for example, the demand for greater electrical generation and cooling system capacities is unlikely to diminish, particularly if directed energy weapons fulfil their current promise.

Shipbuilding as part of a continuous design and production program

One of the key advantages of the continuous design and production model to which Australia is transitioning is the ability to use national shipbuilding capability for strategic advantage, responding to strategic circumstances and technological opportunities. It provides current and future opportunities to choose to keep the current fleet size or to increase it by varying production tempo and warship service life. For example, a 20-year model produces a more rapid production tempo and hence the ability to respond more rapidly to strategic or technological change and to be a fast and agile follower. This would enable the future frigate to be built in flights, which balances the benefits of using a proven ship design with an evolutionary approach to capability; adding new systems to newer vessels and possibly retrofitting earlier models where possible.

This analysis hasn’t considered the impact of the 20- or 30-year options on the design and construction process or on approaches to maintenance. It might be that one or the other leads to greater efficiencies. If the costs for the two options are roughly equal, then a difference in production or in-service maintenance efficiencies could be a significant determinant.4 What is certain is that, when viewing the production of combat capability as a national enterprise, it’s necessary to understand the impact on defence industry just as much as the impact on the Navy and Defence organisations. What’s not immediately clear from the cost information on the current Australian warships is whether a 20-year or 30-year service life is better suited to different types of vessel. A general observation of international navies suggests that larger vessels, such as aircraft carriers and replenishment vessels, tend to have longer service lives (35–40 years and more, with at least one major upgrade), whereas smaller vessels, such as patrol boats, tend to have shorter service lives (15–20 years, mainly without major upgrades). For aircraft carriers, this is probably a reflection of the cost of the air group, with the platform cost representing a larger proportion of the remaining cost of the capability. For smaller vessels and submarines, the margins for adding or changing systems are smaller, so the upgrade cost is more likely to exceed the replacement cost. The maintenance and sustainment requirements for submarines add another layer to be considered. This analysis suggests that the question of service life must be determined for each different program.

Conclusion

The most important conclusion to be drawn from this analysis is that Australia has a choice about how it produces its future warships. In the long run, a 20-year service life model for warships has a similar cost to a 30-year-plus-midlife-upgrade model. Within the uncertainties of our limited data, neither option is intrinsically more expensive. The long-term cost is far more dependent on the capability that’s being installed on a vessel than on whether it’s delivered at build or following an upgrade.

Australia has typically carried out mid-life upgrades to extend the service life of warships, and the upgraded vessels have been operationally effective vessels.

The question to be answered in the Australian context is whether the mid-life upgrade is necessary or desirable for the future frigate and submarine programs. A shipbuilding program that prioritises low costs would leave open the possibility for either option to be considered at the time an upgrade is being considered. For example, if the plan to upgrade the Adelaide-class FFGs had included an option to replace them at an earlier date, that may have been a more cost-effective means of improving the RAN’s capability. And even that would have been a significant change to standard practice in Australia.

However, the current political environment suggests that the Australian Government is planning to stand up a continuous shipbuilding enterprise. Reducing the planned service life of future warships to 20 years could help to improve the sustainability of such an endeavour. For a fleet of 12 large surface combatants and 12 submarines, a 20-year service life would allow for a continuous build tempo of one surface ship and one submarine roughly every 18–20 months. That’s quite slow, but faster—and so more sustainable—than the tempo required for a 30-year service life, unless the fleet size grows.

A national enterprise-wide view does not mean Australia will be forced to commit to one option; rather, it means decisions can be made to suit our capability and circumstances. The transition to a continuous build approach, at least across frigate and submarine construction, is a large and complex task; anything that simplifies the task will contribute to lower risk, lower cost and greater likelihood of success. So, there’s merit in Australia choosing to plan for a 20-year service life for the first batches of new frigates and submarines, with a suitable growth margin to enable combat capabilities to be kept up-to-date through that service life. Once the cadence of design and construction is established, Australia can look again at its options for warship service life.

Appendix: Build, upgrade and sustainment costs for RAN vessels

Table A1: Build, upgrade and sustainment costs for RAN vessels (A$ million 2016)

This table uses data from Defence annual reports for the build, upgrade and average sustainment costs of three RAN vessel classes: the Adelaide-class guided missile frigate, the Collins-class attack submarine, and the Anzac-class frigate. The intended result is a cost comparison between a 30-year model that includes a mid-life service upgrade and a 20-year model that includes no upgrade.

The assumption is that the build would produce a vessel with 20 years of useful (in a capability sense) service life and that an upgrade would provide a further 10 years. (In practice, a vessel would be out of service for some time during the upgrade, but for our purposes we assume a total of roughly 30 years in service.)

We decided that the annual cost per vessel for each model would be the best common level at which to compare the two different models. Each cost was therefore broken down to a cost per year, per vessel. The 30-year model represents the sum of build, upgrade and sustainment costs (per ship / per year). The 20-year model excludes the costs of upgrading the vessels.

Notes

1 Plan to Reform Support Ship Repair and Management Practices (the Rizzo Review), Department of Defence, Canberra, July 2011, p. 36.

2 Wayne Biddle, ‘Main shipbuilder gets Navy contract for a new destroyer’, New York Times, 3 April 1985, online.

3 Ronald O’Rourke, Navy DDG-51 and DDG-1000 destroyer programs: background and issues for Congress, Congressional Research Service, 20 May 2016, p. 5.

4 This is consistent with previous, much longer studies. See the Australian Naval Shipbuilding and Repair Sector Strategic Plan, Department of Defence, Canberra, 2002, p. 173.

About the Authors

Alastair Cooper is a public servant and active Royal Australian Navy Reservist.

James Mugg is a researcher at ASPI with primary interests in defence capability development and Middle‑East security.

For more information on issues and events that shape our world, please visit the CSS Blog Network or browse our Digital Library.